- ABOUT

- Markets

- Products

- Responsibility

- Investors

- Careers

- Contact

- Search

We develop transportation strategies to reduce our carbon footprint and maximize the amount of product shipped per mile using the most environmentally friendly modes of transportation whenever possible.

Oil-Dri strives to maximize the transportation of products on railcars via bulk or intermodal shipments utilizing the branch lines at our manufacturing facilities. Having a spur on-site at five of our plants enables us to efficiently load railcars without the need of additional modes of transportation, thereby greatly reducing greenhouse gas emissions and saving fuel. Every container shipped by rail means one less long-haul truck on the highway, easing congestion, reducing pollution, and saving energy. Not only does this limit our environmental impact, but it helps lower costs to our customers and ultimately to the consumer.

A truck hauling heavy products can reach its legal weight limit long before its trailer is full. Therefore, more trucks are required to deliver the same amount of heavy goods compared to lighter weight products. The more trucks on the road, the more carbon emmissions are produced. Cat litter is a heavy product that is traditionally packaged by the pound, with a consumer perception that a lower price per pound is a better value. However, users fill their litter box to a desired level based on volume, not by weight. In 2011, Oil-Dri changed the industry with the introduction of Lightweight litter with our naturally porous, light-density clay that is up to 50% lighter in weight and provides the same volume or number of uses as other traditional scoopable litter. We then applied the same volume-based approach to our industrial absorbent business. We are now able to load more units on every truck, which greatly reduces the number of vehicles on the road. As a result, less fuel is consumed, and carbon emissions are reduced. It’s a big win for both consumers and the environment.

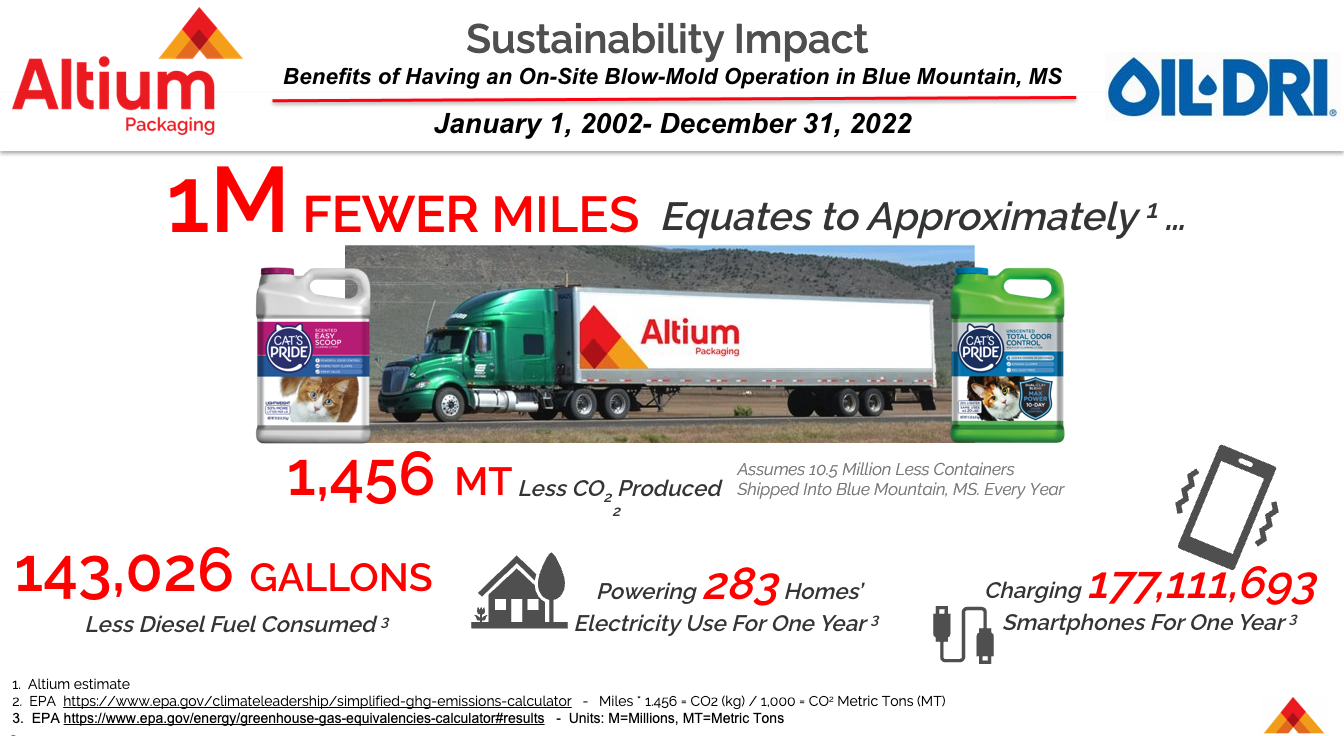

Oil-Dri is proud to partner with Altium Packaging for its on-site blow mold operation at its Blue Mountain, Mississippi manufacturing facility. By producing plastic jugs on-site, Oil-Dri is able to significantly decrease the number of incoming truckloads from Altium Packaging. As a result, less diesel fuel is consumed, and carbon emissions are reduced. This partnership supports Oil-Dri’s sustainability efforts to reduce its environmental footprint.

© 2024 Oil-Dri Corporation of America. All Rights Reserved.